Creating Cove Lighting Without Building A Cove With The Elliptipar S41X Series

You probably don't need me to explain the benefits of cove lighting. Indirect light sources that illuminate ceilings and walls create luminous spaces without the noticeable glare of direct point sources. Indirect Lighitng can also help define spaces as you call attention to the shapes of walls and ceilings, softly defining the volume of the space.

As LED has come of age, there are more ways to make a cove light than ever before, but the most common method - LED tape in extrusion - is not the answer if you want functional light that will provide enough illumination to actually make a space workable. For that you need a performance product with optics and enough punch to fully illuminate the ceiling or wall.

For that…you need to look to a company like Elliptipar. Elliptipar (The Lighting Quotient) has been focused on illuminating surfaces for decades. What’s really exciting is that their efficacies increased dramatically in the last few years, making them a viable solution for day-to-day projects. Here’s where I want to pause. The go to solution from contractors on cove lighting is tape and extrusion. The pressure will be to go to a tape light solution because contractors know it’s the cheapest per linear foot. However, all in, I can tell you that’s not the case and here’s why.

Tape and extrusion for functional cove lighting isn’t the answer.

Listen, if you’re designing a niche cove to illuminate a display at the hostess desk of a restaurant, tape light is absolutely the way to go. But if you’re trying to illuminate a ceiling down the length of a hospital hallway, you need something with punch. I can already here the concern.

But the cost of building out a properly designed cove will overrun the project

Not anymore.

It’s time to get a cove without building the cove. Late last year, Elliptipar introduced the S41X series. (Side note the caller above provides descriptions and links to cut sheets) The series is available in different profiles meant to compliment the architecture of the space. These profiles build a cove for you - creating a wall mounted, indirect light source for washing a ceiling. This design eliminates the need for contractors to build out a cove and integral drivers mean that it’s not necessary for contractors to figure out where to locate drivers and run feed wires. This series as form factors that are small enough to remain ADA compliant and with lumen outputs designed for everyday spaces with 8-10 foot ceiling heights.

The Difference Is Performance

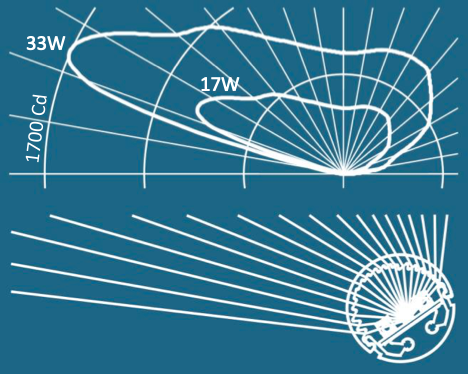

The key difference between Elliptipar and other indirect products is the true indirect optics and performance designed for performance lighting. There are lots of “blob of light” 120 degree output fixtures out there. The pattern shown above is one TLQ has defined over the years and is the only way to get truly exceptional (and functional) indirect lighting.

Let me know if you want to learn more about these products or see a sample. TLQ has the best lighting applications team in the business and can help us figure out light levels, fixture spacing and all of the details that will make your next project look amazing.